Our Service

Powering Calm Behind Every Charger You Ship

For the Teams Who Cannot Afford a Failed Launch

Whether you are a sourcing manager, a product manager, or a brand owner, you need a factory partner who communicates like an in-house team – especially when timelines are tight and expectations are high.

Clarity instead of endless back-and-forth

· For the sourcing manager

You balance cost, risk and lead time. WECENT gives you structured quotations, clear MOQ rules, and transparent production schedules, so you can report to your stakeholders with certainty instead of guesswork.

Specs that stay aligned from PDF to mass production

· For the product manager

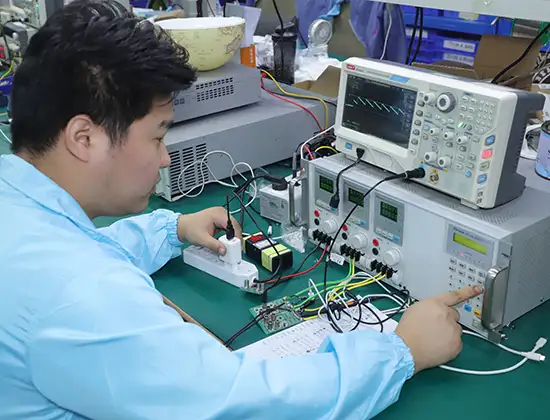

You worry about how every port, color and charging curve translates into real hardware. Our engineers stay in the loop during DFM, samples and reliability testing, so design intent does not get lost on the production line.

A quiet back-end that protects your front-end reputation

· For the brand & channel owner

Your logo will be on the box with custom packaging. WECENT focuses on stable quality, compliant certifications and responsive after-sales, so your customers remember the charging experience – not the problems behind it.

From First Inquiry to After-Sales – One Connected Service Journey

Our services follow the full lifecycle of your charger project. The original “Pre-Sales / In-Sales / After-Sales” structure is kept, but now strengthened with clearer touchpoints, communication, and risk-control steps.

Pre-Sales

To help you make informed decisions

In-Production

To keep every batch on track

After-Sales

To stand behind every charger you sell

Communication That Feels Like an In-House Team

Good hardware without good communication still leads to bad projects. That is why we design our service around how we talk, document, and respond – not just around how we manufacture.

Single owner

Each project has a dedicated manager who understands your business model and keeps all threads connected.

Sales + engineering

Sales, PM and engineers join key calls together, decisions made with both commercial and technical clarity.

Multi-channel

Email, chat and online meetings – we adapt to your workflow to reduce response friction across time-zones.

Structured updates

From order confirmation to shipment, you receive structured updates instead of scattered messages.

How We Communicate Through Your Project

1. Kick-off

We map out SKUs, certifications, deadlines and risk points, then confirm them in writing.

2. Sample & testing stage

We share testing suggestions and align on acceptance standards with your team.

3. Mass production

We send key status points: material ready, line start, mid-production checks, and pre-shipment inspection.

4. After-sales

If any field issue appears, you contact the same team; they already know your history and requirements.

When Something Goes Wrong With Your Order

As soon as you report a problem, your project owner confirms receipt and starts collecting basic information and photos.

We clarify the impact: which batch, which quantity, which customer, and what deadline is at risk, so we focus on the right priority.

Our engineering and quality teams analyse samples, test conditions, and records to determine whether it is design, material, process or logistics related.

Together we agree on actions such as rework, replacement, or adjusted future batches, always aligning with your market commitments.

We update process controls or documentation, then close the loop with you so the same issue does not repeat in later orders.

2-Year Warranty Promise

Two Years of Warranty for Long-Term Peace of Mind