Inspect Products · GaN & Wireless Charger QC

Inspect Products: Turning Every Charger into a Consistent Promise.

Live Charger QC Snapshot

Inspection gates passed

ESD control

Sampling plan

Safety checkpoints

For the people who cannot afford “maybe” on quality.

Instead of walking you through every screw on the line, we focus on what matters to you: how inspection turns into fewer complaints and more repeat orders.

For the brand owner

For the brands in the spotlight

For the e-commerce & retail teams

For the teams watching review stars

For purchasing & compliance

For the people holding the spec sheet

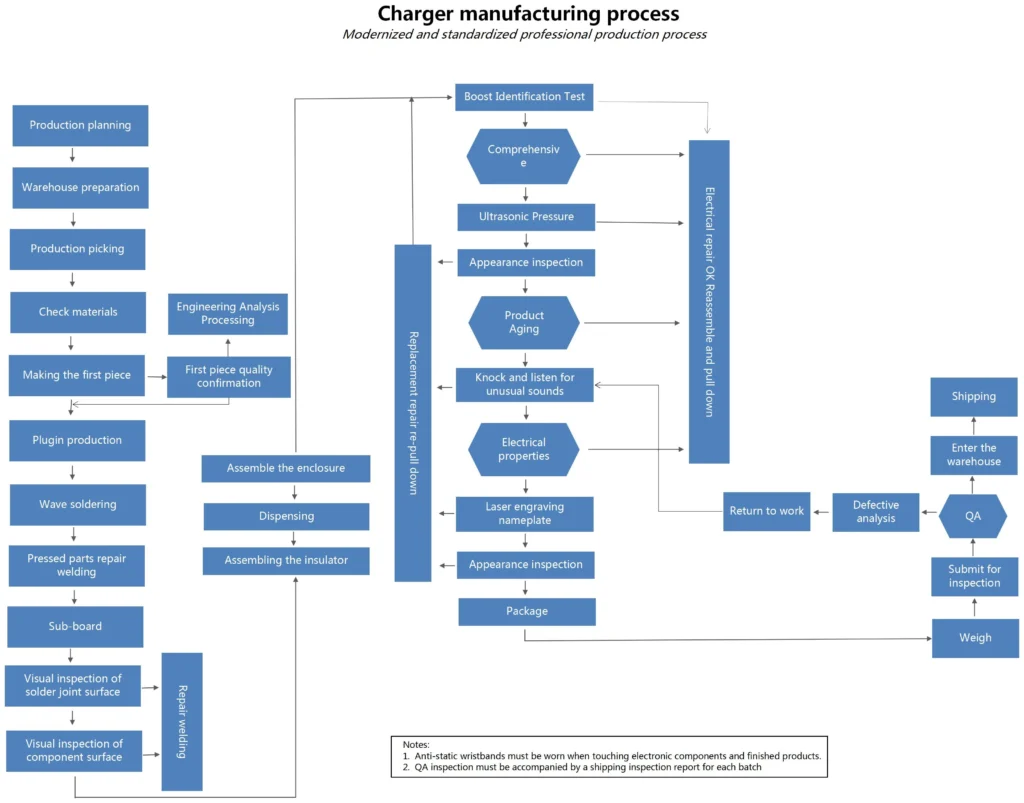

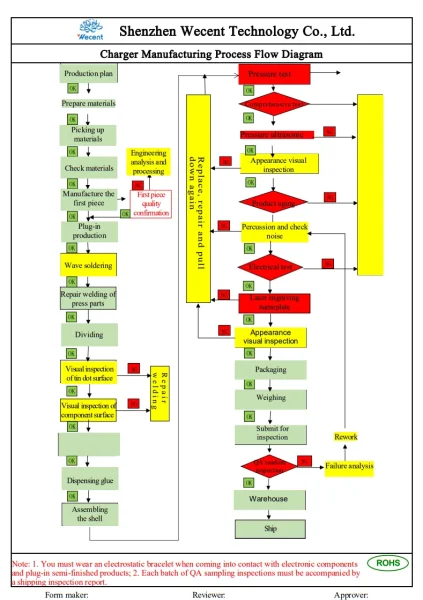

How We Inspect Your Chargers

Internally, each product has a detailed “Manufacturing Operation Instruction” sheet covering tools, ESD requirements, operation contents, cautions and judgments for every station. For you, we summarise this into a few understandable inspection gates — enough to feel in control, without drowning in documentation.

From raw materials to packed cartons — in clear checkpoints.

Our overall charger manufacturing flow includes material preparation and checking, first-piece quality confirmation, plug-in production, wave soldering, multiple visual inspections, product aging, pressure tests, comprehensive electrical tests, QA sampling, and warehouse release.

Gate 01 · Before the line

Incoming material & BOM verification

Gate 02 · PCBA in process

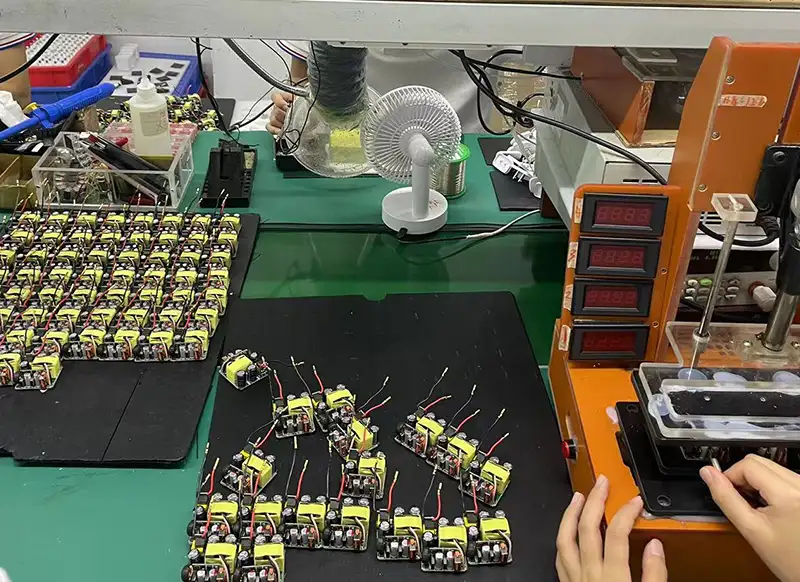

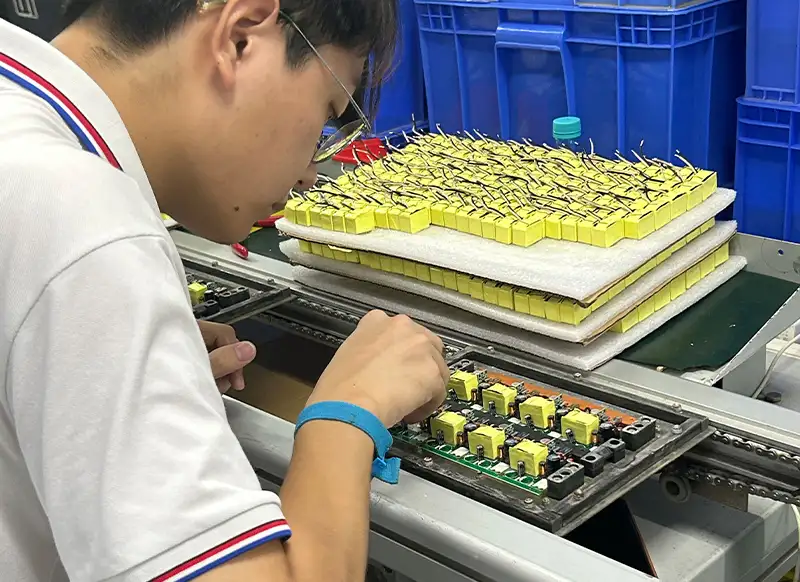

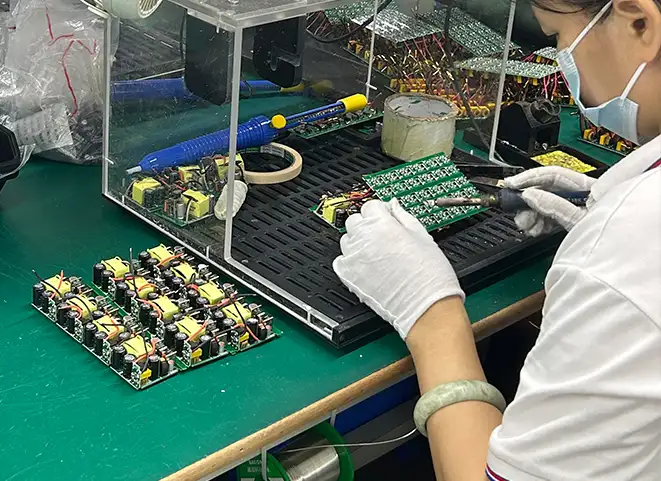

Plug-in, wave soldering & ESD-safe handling

Gate 03 · Board-level inspection

Tin surface & component visual checks

Gate 04 · Function & safety

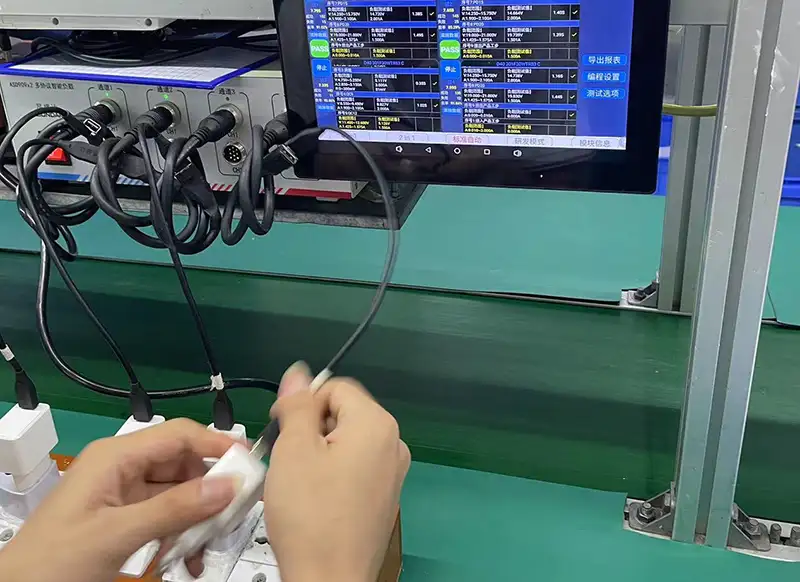

Electrical test, pressure test & aging

Gate 05 · Before shipment

QA sampling & shipment inspection report

What We Actually Measure

Whether it is a 20W phone charger or a 240W laptop GaN charger with multiple Type-C and USB-A ports, each product family comes with its own matrix of power profiles, protocols and plug standards. Our inspection focuses on the parameters that translate directly into user experience and compliance.

| CATEGORY | WHAT WE CHECK | WHAT YOUR CUSTOMER FEELS |

|---|---|---|

| Power & ports | That single-port and multi-port output combinations (e.g. 140W + 100W, 65W + 20W) behave according to the agreed spec for your model series. | “My laptop and phone both charge fast, and the ports share power intelligently.” |

| Protocols | That supported standards such as PD2.0/3.0/3.1, QC, PPS, FCP, SCP, AFC and Apple 2.4A are functioning as intended for your chosen models. | “It just works with my devices — no random disconnects, no slow fallback charging.” |

| Safety & compliance | That safety functions and hi-pot tests align with the certification standards (CE, FCC, RoHS and others) you target in your market. | “The charger stays cool, feels safe, and carries the marks my market requires.” |

| Appearance | That shells, logos, engravings and labels are clean, aligned and consistent with your brand guidelines, with additional visual inspections before and after assembly. | “The product looks premium out of the box — no scratches, misprints or crooked labels.” |

| Reliability | That chargers pass aging tests and percussion/noise checks in the production flow, so that early-life failures are minimised before shipping. | “It keeps working after months of daily use, not just in the first week.” |

Certified for Your Market, Ready for Your Brand

From CE, FCC and RoHS to PSE, KC and more, each WECENT charger comes with the compliance foundation your listings and audits demand, so your team can focus on sales instead of paperwork. We build, test and document to the standards of your target countries from day one, turning complex regulations into a simple, reliable green light for every shipment.

Modernized Charger Manufacturing, Visualized

From production planning and material checks to PCBA soldering, product aging, QA sampling and shipping, this flow maps how every WECENT charger travels through controlled steps and inspection gates. It gives your team a clear view of where quality is built in, and why each shipment arrives consistent, compliant, and launch-ready.